The yacht survey

A survey of the yacht is made, which could employ the ARK survey kit if required, to record a variety of dimensions and angles which are recorded on a standard form.

These determine:

- The ideal fixing positions for the transom plates

- Their height above the water line and horizontal separation

- The height above the waterline of the yacht cockpit floor, steps and fold down platform (if present)

- The position of the pushpit top railing

- The backstay arrangements

- Details of the dinghy if known at the time

The surveys can be done by ARK if geographically convenient in England, or by a distributor. In the event of none being close to the yacht location, we would usually survey an identical model locally. Each distributor will have the Measuring Tool Kit.

Fitting to the transom

There are 3 items fixed to each side of the yacht, bolted through the transom surround.

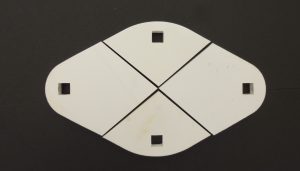

- EPDM90 white rubber shims which are built up and contoured by a sander to match the hull shape at that point. Each has a square hole. Laid out together they are the shape of the Transom plate they sit under.

- A flat stainless steel Transom Plate to sit over the above shims. This contains 4 square holes.

- The Transom Bracket, to carry the Track Arm. This has 4 curved slots above the Plate holes.

4 x M10 stainless steel (A4) coach bolts are inserted into the 4 holes. Some transom surrounds maybe so restricted that it is not possible to set the Transom Plate vertically, so they maybe to be up to 16 degrees off vertical either way, then the Transom Bracket slots allow the Bracket (which sits 16mm above the hull facia) to then be rotated to the vertical position and fastened down tight. Being a coach bolt with a square shank under the head, the shank engages into the slot prevent it from rotating so permitting a one person job, who then goes inside the hull to tighten the bolts.

On the inside of the hull, the coach bolts pass through a 50x50mm plate washer and one or more tapered thickness washers which are used to build up the bolting surface to being square to the bolt shaft. The standard length of coach bolt is 70mm, adequate for almost all situations. If the survey records a very curved drop away transom facia, then the kit will contain longer bolts. The fitter may choose to then cut off any unwanted length of the bolt.

Transom reinforcement

It is important to realise that unlike a davit where the small base bears an immense bending moment, the Dinghy Derrick design places very little such loading given that the mount is a hinge. There is some compression under lifting and then some shear force downwards when the Track Arm is upright, but again quite modest loads. Only when the Track Arm is fully down in launch mode resting on it’s lower pin, will any rotational force be applied, but by then the dinghy is floating and not loading the frame. So it is only the weight of the frame being borne. None the less, if the fitter is concerned that the yacht hull is too thin even for this load, subject to what lies behind the hull facia, this may readily be reinforced. A very simple approach to this would be a panel of marine plywood (7 or 9 ply) laid inside extending to the corners, under which is spread a silicon sealant to say 10mm. The Brackets and plates are bolted through lightly to compress the ply/sealant and extrude some over the corners and side panels, so the plywood distributes the load over a wider area and effectively thickens the hull and cushions the compression.